JCB

The history of the world-famous manufacturer of heavy construction equipment company JCB begins in the UK in 1945 with an ordinary garage, in which the founder of the company, 29-year-old Joseph Cyril Bumford, worked. The idea to start his own business came to Bumford in a period of despair.

The fact is that in 1945 he worked at the construction company Bamfords Ltd, which was headed by his uncle. The affairs of the company did not go well, and the head of the company did not think of anything better than how to fire his nephew. Bumford, whose son was about to be born, but had only enough money for a month, he decided to take a chance and bought a welding machine for 1 pound. Then he rented a garage for 30 shillings a week and there he made his first invention - a dump truck.

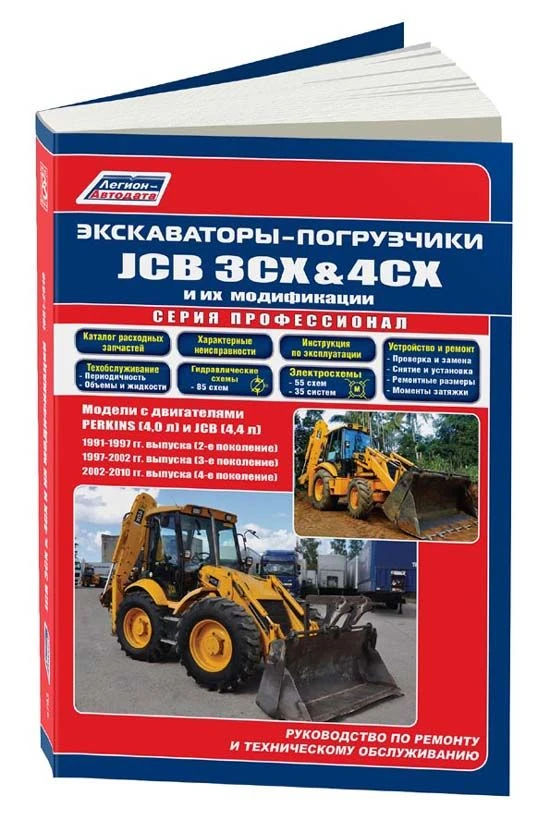

3CX/4CX ECO, we fit a traditional manual control system as standard, with a choice of three control patterns – JCB X, SAE+ and ISO+. With joystick-controlled loader operations on Advanced EasyControl, it’s comfortable, logical and easy to control the loader end of a 3CX or 4CX. COMFORT AND EASE OF USE 3CX/4CX BACKHOE LOADER 11 6 7 5 JCB X. JCB's new multi-functional instrument control panel can provide current and average fuel consumption. 7 So that operators feel right at home in the. 3CX and 4CX SUPER, we fit a traditional manual. JCB 3CX, 4CX ECO (JCB TIER 4 ENGINE) Backhoe Loader Operator Manual (En – 9821/3000 – ISSUE 5 – OCTOBER 2013) JCB 3CX, 4CX, 5CX BACKHOE LOADER Operator’s Manual (9831/0400 ISSUE 8 – 03/2018).

Bumford requested 90 pounds for his invention in the market. One local farmer bought this cart from him, but for 45 pounds, and in addition gave his old cart. Joseph repaired it and after a week sold it for 45 pounds, thereby receiving a total of 90 pounds, as he wanted. Given that many in his hometown earned 1.5 pounds a week, Bamford became rich overnight.

He was not going to stop there, since his goal was to wipe his uncle’s nose and get ahead of Bamfords Ltd. in profit. Bumford went to the bank for a loan to develop the company. Money was given to him, but soon the bank informed Joseph that he should return it within a week. Bamford with great difficulty returned the money and then decided for himself that he would never take a loan.

This was the first postulate of his business. Without becoming discouraged, Joseph invents a trailer with a manual mechanism, the body lifted onto the chassis, and all the contents spilled out of it. Such an invention was immediately liked by local farmers and began to be in great demand.

In 1947, Bumford improved this trailer with a hydraulic lift, with the help of which the tractor operator, without getting off the seat, could empty the body. A further invention from the JCBcompany (by that time already 6 people were working in it) were Si-hydraulic hydraulic forks, which were attached to the tractor and simplified the work of farmers.

In 1948, the first JCB Mk 1 backhoe loader began to be created, which was launched into serial production in 1953. Bumford saw this idea from the Norwegian inventor of the excavator. This excavator was awkward, and the Englishman saw the potential in it, adding a mechanical shovel to his invention. So the first Mk 1 appeared, which changed the activities of JCB in favor of construction equipment.

All in the same 1953, the official company logo was developed, the creation of which Leslie Smith worked. The logo was designed by Leslie Smith, the tilt level is set at 18 degrees from the horizontal and 22 degrees from the vertical.

In the 1950s, JCB arrived at 3 million pounds. Almost all the profits were invested in the design of their future machines, so that they meet the needs of customers in all respects.

In 1960, JCB's technology first appeared on the North American market. In 1964, the famousJCB 4C backhoe loaders were sold with a total of 3,000 units. This was due to advertising that was broadcast throughout England and which cost Bumford just 5 pounds. JCBemployee Noel Hooper came up with a trick for which he received a reward.

The advertisement was as follows: Hooper on a 4C excavator rested against the asphalt with a mechanical shovel and bucket, then he turned on the hydraulics, and the car rose to such a height that a Cadillac could freely pass under it. In an instant, the whole country learned about the power and abilities of the 4C excavator. For such a trick, Bamfort was nicknamed the circus performer, and this prompted the head of the JCB to open his own 'JCB Circus', in which the same excavators perform tricks.

JCB Circus performances are still in demand at exhibitions, presentations and receptions. In 1964, Bumford issued a bonus of over £ 250,000 to his employees. For this, the team gave him a bronze bust of himself (he is still kept in the JCB Museum, which was organized in his office, where Joseph Bumford worked in the 70-80s, in the Drawing Department and Design Center).

In 1965, another unique invention from JCB appeared on the market - a 360-degree excavator. In 1967, a 3D backhoe loader was developed (a small copy of the JCB 4C). The uniqueness and novelty of such an excavator was associated with the marketing move (it was impossible to allow the latest sales excavators to be the last). Firstly, an electric kettle was equipped in the cabin of the car so that the operator could make tea on the spot.

The second trick was related to the newspaper ad, which said that the first 100 customers who bought this excavator would receive an electric kettle from the hands of Bumford himself, who would personally bring it on his Rolls-Royce. This “trump ace” from the sleeve of the head of the company did his job.

The first 100 cars with frantic excitement were bought during the day, and the comfort of the cabin became the brand name of JCB (now the cabin is equipped with an air conditioning system). In 1977, the famous Loadall under the JCB brand was launched, and it became famous thanks to the fact that it could not only lift the load, but also transport it.

In 1978, JCB began operations in India. Further activities of the company were aimed at improving the mechanisms of future inventions, developing design and innovative solutions. In 1990, the Total Quality Management program was developed, which was the guarantor of the quality of products, since according to it, on a quarterly basis, 20% of employees were tested according to the estimates of the production process, achieved goals, proposals, projects and leadership style.

In 1991, JCB entered into an agreement with the Japanese company Sumitom for the joint production of excavators. Then she begins to produce integral tractors Fastrac, capable of speeds of more than 70 km / h. Having managed to open subsidiaries in some countries, JCB in 1991 opened a similar enterprise in Russia (Lonmady company), the main purpose of which was to promote British technology in the Russian market.

In the 1990s, additional factories for the production of JCB equipment were opened in the United States (Georgia) and in Brazil. In 2004, JCB began manufacturing JCB444 diesel engines, which were developed by its own design bureau. In 2005, the German company Vibromax became part of the British manufacturer, which in the same year managed to open a new factory in China.

In 2009, JCB announced that the manufacturing center in India would become the largest manufacturer of forklifts. JCB today is the world's largest manufacturer of heavy construction equipment, which has more than 300 items in its assortment.

Every day, more than 15 factories located on 4 continents produce products (mini-tractors, soil rollers, ramming equipment, wheeled and tracked excavators, backhoe loaders, etc.) exported to more than 150 countries.